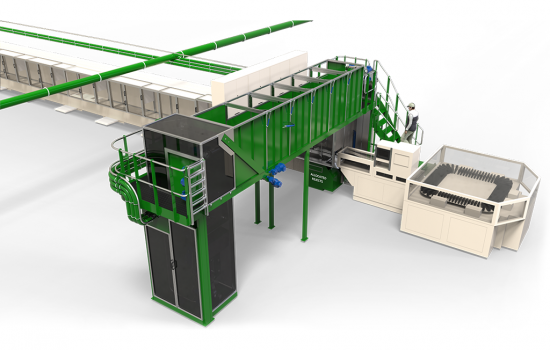

Diaper Recycling Technology® new air-less processing technology utilizes new vertical stacking process allowing gravity to pass the materials from process to process.

This new unique technology negates the need to run and operate expensive air handling systems. Thus, 90 – 95% of ongoing energy costs can be saved versus conventional recycling technology.

Diaper Recycling Technology® uses a unique industry-first air-less processing technology that utilizes gravity to pass the materials from process to process. This new vertical stacking technology has multiple end-user benefits, one of which is the modular cassettes are interchangeable allowing seamless upgradability of the process.

Process modules such as plastic purification and pulp/SAM separation can be added and/or removed as and when desired.

Need more capacity? Simply plug multiple modules together to boost capacity.

Gentle SAP Removal

“It’s all about BEING GENTLE with your materials”

Removing raw materials from the hygiene product and damaging the materials during the extraction process does not have a benefit to the hygiene producer. With the latest generation SAPs, any damaged SAP being returned into the core former can reduce product performance significantly. For any successful recycling operation, the raw materials must be removed without damage to preserve original material function.

Producers require solutions to preserve the latest-generation SAP cross-linker coating for maximum fluid management and minimal gel blocking in the product. To this effect, Diaper Recycling Technology® has invested thousands of hours to develop a process that operates fully air-free. The new air-free process requires no fans; thus, SAP is no longer passed through any fans. Contact with high speed rotating impellers is avoided, and the delicate cross-linker outer surface of the SAP is protected. By utilizing specifically designed unit operations to gently remove the SAP, our technology allows you to recycle SAP without impacting your product performance.

With solutions starting at 3 sqm., Diaper Recycling Technology’s new vertical stacking process technology allows floor space utilization to be maximized. Conventional recycling technology on the other hand typically requires between 400 – 800 sqm of space to operate.

Diaper Recycling Technology® Generation 6 In-Line technology has been boosted to allow material

in-feeds of up to 4 converters. Central recycling modules process up to 500 KGs per hour while adding further capacity can easily be achieved by adding more modules.

Diaper Recycling Technology® total product portfolio covers hygiene factories of any size ranging from 1 to 50 converters.

Contaminant FREE | “It’s all about PURITY”

Sacrificing your product quality, putting the consumer at risk, putting your brand at risk are simply not acceptable for today’s hygiene companies.

All recycled raw material streams need to be 100% pure and contamination-free.

Our newly developed technology ensures

A pure plastic stream

Effective with PE, PP, PET, PLA, and more. Plastic emerges from the process clean and ready to be pelletized.

A pure pulp stream

Softwoods, hardwoods, viscose, etc. All emerge from the process, plastic-free.

The risk of specks and other contaminants appearing in the finished product are eliminated.

A pure SAP stream

Works with all generations of SAP materials including latest cross-linker SAP technology.

Zero external contamination risks

Our inline recycling technology is fully enclosed thus eliminating all contamination risks related to human activities that can impact your operation such as earplugs, chewing gum, food, etc.